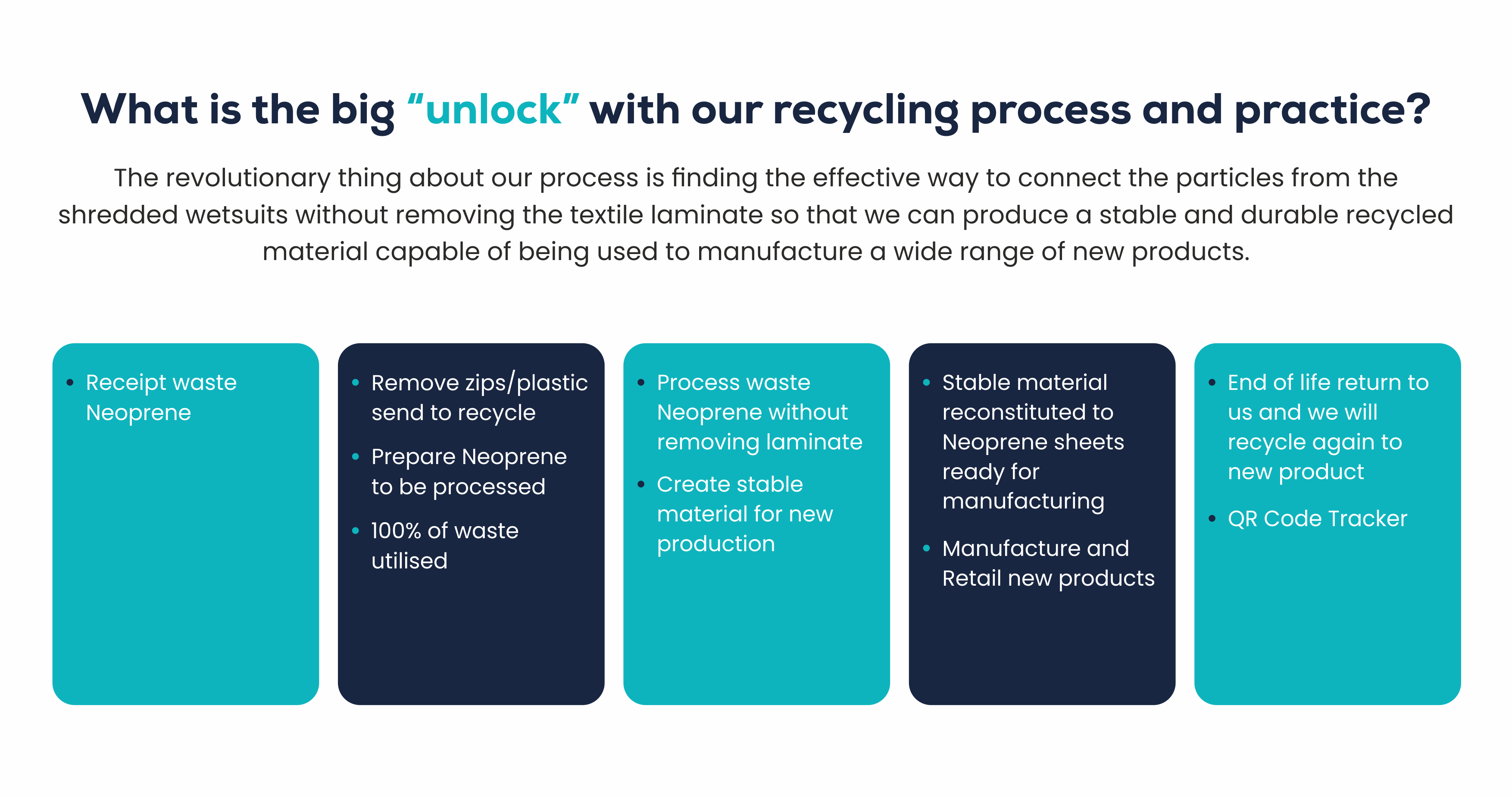

The technology being used to deliver recycled sheets of neoprene that are stable and ready for manufacturing into alternative new products has been in development for the past six years. We are finally ready to launch the service. The process is proprietary and complex. The schematic below gives an overview of how we execute the actual reprocessing of the waste neoprene material.

The How

Stop 1 million wetsuits going to landfill

- We have added the capability of laminating almost any material on top of the recycled neoprene (including environmentally friendly textiles e.g. those made from recycled PET bottles)

- This significantly extends the material and product ranges we can offer

- There is no burning or melting in our process and no toxic chemicals are emitted

- Vulcan rubber is processed together with the rest of the particles

- We also detach any sub materials used in the process of manufacturing wetsuits such as zips, snap buttons and other plastic or metal items and submit them to partner facilities where they are also recycled

- The glue that we will be using will meet the criteria set out in the REACH regulation, PVC free and RoHS Directives and hence it will conform to the requirement of EU legislation

- The Aqua glue has been the standard in the premium neoprene material lamination for the last five to ten years and indeed it is considered the greenest approach to applying any kind of textile on the neoprene foam

- As such and considering the essence of our project and technology, we intend to also use this type of glue for our lamination activities to ensure that the overall result and end material is as sustainable as possible.

Neoprene Waste Collection

The waste collection process will be achieved with the brand and retail partners, initially in the UK and Europe, to collect, return, recycle, and retail the new consumer products. The even better news is that these recycled items can be then returned at the end of their life and recycled again and again!

We are proud to begin the collection process with a leader in wetsuit and neoprene innovation and a brand and founder who cares deeply about the environment Finisterre.

The process is broad as below and will be the template for future partnerships with retailers and brands.

We are excited to share the details of future partnerships as they are announced. We have several in the pipeline and hope to make these announcements very soon.

We are initially focussed on the wetsuit/neoprene water sports where we identify that over 8,000 tonnes of wetsuits are ending up in landfill/incineration.

However, there is a huge neoprene industry that represents currently over 300,000 metric tonnes. We believe that annually 20% of this will reach end of life and then be disposed of again via landfill or incineration. The source for this data See Here

Global Chloroprene Rubber Market to Reach 324.8 Thousand Metric Tonnes by 2026

Chloroprene rubber or polychloroprene rubber or neoprene, is a synthetic rubber that is produced through chloroprene’s polymerization. Chloroprene rubber (CR) exhibits superior properties such as favorable chemical stability and flexibility over a broad temperature range, which contributes to its widespread use in a range of applications including as a raw material in modifying adhesives as well as the production of latex products, among others. Increase in private public investments into construction sector and focus on infrastructure development projects especially in developing economies remain critical to the demand for CR in building & construction industry. Rising demand for cold- and weather-resistant products such as wetsuits and marine products is also a major driver of growth. Also driving demand will be the increasing use of CR in electric cables to meet the ever-growing need for energy and subsequent the subsequent increase in the number of power transmission lines being established. The market stands to benefit from the inefficiencies associated with competitive products such as natural rubber, synthetic SBR and isoprene. With the COVID-19 pandemic denting prospects in industrial, manufacturing, construction and automotive industries, the demand for chloroprene rubber is also being adversely impacted. The recovering demand for industrial rubber products, adhesives and automobiles is thus a vital determinant of growth in the CR market.

The market research was completed Global Industry Analysts Inc., and published 16 March 2022